What advanced manufacturing processes and technologies, such as welding and cutting processes, are used in the manufacturing process of luffing jib tower cranes?

In the manufacturing process of luffing jib tower cranes, Jiangsu Tengfa relies on its profound technical background and continuous innovative spirit to integrate a number of advanced manufacturing processes and technologies to ensure that each jib tower crane not only meets industry standards, but also achieves excellent levels in stability, safety and efficiency.

As the core link in the structural manufacturing of tower cranes, the quality of welding is directly related to the overall strength and safety of the product. Jiangsu Tengfa has introduced a fully automatic welding robot system, a technological innovation that greatly improves the accuracy and efficiency of welding. The fully automatic welding robot can accurately control the welding path, speed and temperature through preset programs to achieve uniformity and consistency of the weld, effectively avoiding welding defects caused by human factors. In addition, robot welding also greatly reduces the thermal stress generated during welding, improves the strength and toughness of the weld, and lays a solid foundation for the structural stability of the jib tower crane.

In the manufacturing process of luffing jib tower cranes, the processing accuracy of parts is crucial. Tengfa uses an advanced CNC gantry drilling and milling center, which integrates a high-precision servo drive system, an advanced tool library management system, and an intelligent detection feedback system, and can efficiently complete the precision machining of parts with complex shapes. Compared with traditional cutting processes, the CNC gantry drilling and milling center not only improves processing efficiency, but more importantly, it ensures the dimensional accuracy and surface quality of parts, which is especially important for key components such as the boom and slewing platform of the boom tower crane, ensuring its stability and durability under extreme working conditions.

In addition to the CNC gantry drilling and milling center, Tengfa is also equipped with a high-performance machining center for processing various small precision parts in the tower crane. The machining center can achieve high-precision machining of complex surfaces through multi-axis linkage control, and can achieve micron-level machining accuracy for both the hinged parts of the boom and other precision parts. This not only improves the overall performance of the product, but also shortens the production cycle and enhances market competitiveness.

The boom tower crane is exposed to the outdoor environment for a long time, and has extremely high requirements for anti-corrosion performance. The automatic spraying production line introduced by Tengfa ensures uniform coating and strong adhesion through precise spraying control and efficient exhaust gas treatment system, effectively improving the anti-corrosion performance and service life of the product. At the same time, automatic spraying also improves production efficiency, reduces labor costs, makes the product appearance more beautiful, and enhances the brand image.

In the entire manufacturing process, Tengfa has also incorporated an intelligent production management system, including material tracking, production plan optimization, real-time analysis of quality data, etc., to achieve full-chain information management from raw material storage to finished product delivery. Especially in terms of quality control, Tengfa uses advanced non-destructive testing technologies such as ultrasonic flaw detection and magnetic particle flaw detection to strictly test welding joints and important structural components to ensure that the quality of each link is controllable, further improving the safety and reliability of boom tower cranes.

In order to ensure the overall quality of boom tower cranes, Tengfa actively optimizes the supporting supply chain and establishes a long-term and stable strategic partnership with industry-leading suppliers. Starting from the procurement of raw materials, we adhere to high standards and strict requirements and select high-quality alloy steels. These materials have high strength, good toughness and fatigue resistance, which are the basis for manufacturing high-performance boom tower cranes. At the same time, through in-depth cooperation with suppliers, Tengfa can flexibly respond to market changes, ensure the timely supply of raw materials and cost control, and provide strong guarantees for the continuous output of high-quality products.

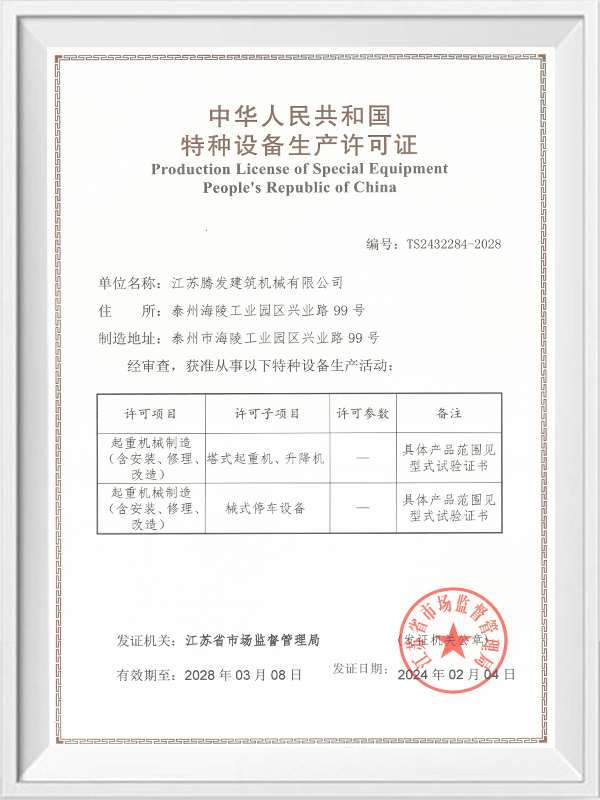

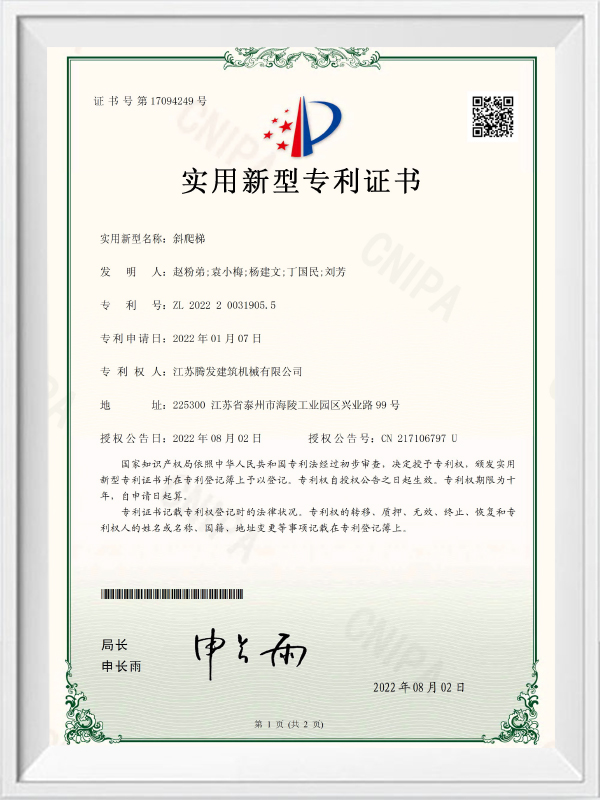

Jiangsu Tengfa is well aware that technological innovation is an inexhaustible driving force for the development of enterprises. Relying on the support of universities and research institutes, the company has continuously increased its investment in technology research and development, and has successively obtained three invention patents and ten utility model patents. The transformation and application of these patented technologies not only improves the technical content of boom tower cranes, but also provides strong technical support for the continuous improvement and upgrading of products. Passing the ISO9001:2015 quality system certification further proves Tengfa's international recognition in quality management.

In the manufacturing process of boom tower cranes, Jiangsu Tengfa introduces advanced equipment and technologies such as fully automatic welding robots, CNC gantry drilling and milling centers, machining centers, and automatic spraying production lines, combined with intelligent production management and strict quality control systems, as well as supply chain optimization and high-standard raw material procurement, to ensure the excellent performance of boom tower cranes in structural stability, machining accuracy, anti-corrosion performance, intelligence level and overall quality, and provide efficient, safe and reliable lifting solutions for industries such as construction and logistics.

English

English русский

русский Español

Español 中文简体

中文简体