Procuring the right tower crane spare parts is a critical task that directly impacts project safety, operational efficiency, and your bottom line. A strategic approach to procurement goes beyond simply finding the lowest price; it's about establishing reliable partnerships, ensuring part quality, and optimizing your total cost of ownership. This comprehensive guide is designed to equip project managers, procurement specialists, and maintenance supervisors with the knowledge and strategies needed to navigate the complex landscape of supplier selection and cost management. We will delve into the key criteria for evaluating suppliers, the nuances between different part types, and practical steps for building a resilient and cost-effective supply chain for your essential equipment needs.

5 Key Criteria for Selecting a Reliable Spare Parts Supplier

Choosing a supplier for tower crane spare parts is a decision that carries significant long-term implications. A reliable partner ensures not only the immediate availability of components but also contributes to the longevity and safety of your heavy machinery. The evaluation process must be thorough, moving beyond basic cost comparisons to assess foundational aspects of the supplier's business. These aspects include their market reputation, which serves as a testament to their historical performance and customer satisfaction levels. Furthermore, the quality assurance protocols they have in place are paramount; these should include certifications, testing procedures, and traceability of materials to guarantee that every part meets stringent OEM standards. Another critical factor is their logistical capability, which encompasses inventory depth, warehouse locations, and shipping partnerships, all of which determine how quickly you can receive a critical component and resume operations after a breakdown.

- Reputation and Experience: Look for suppliers with a proven track record and positive testimonials from other construction or heavy machinery companies.

- Quality Certifications and Standards: Ensure they comply with international quality standards (e.g., ISO) and provide certificates of conformity for parts.

- Inventory Availability and Logistics: Assess the breadth of their inventory and their ability to ship parts quickly, perhaps even offering emergency delivery services.

- Technical Support and Expertise: A good supplier should have knowledgeable staff who can provide technical advice on part selection and troubleshooting.

- Payment Terms and Warranty Policies: Favorable payment options and robust warranty coverage are indicators of a supplier's confidence in their products and their commitment to customer service.

OEM vs. Aftermarket: A Detailed Cost-Benefit Analysis

The debate between choosing Original Equipment Manufacturer (OEM) parts and aftermarket alternatives is a central one in the procurement of tower crane spare parts. OEM parts are produced by the crane's original manufacturer, guaranteeing a perfect fit, specified performance, and full compatibility with your machine. They typically come with a warranty backed by the manufacturer, ensuring peace of mind but at a premium price. Aftermarket parts, on the other hand, are produced by third-party companies. The quality can vary dramatically, from parts that meet or exceed OEM specifications to inferior copies that may compromise safety and performance. The primary advantage is a lower initial cost. This analysis requires a long-term perspective, weighing the higher upfront cost of OEM parts against the potential risks and hidden costs of aftermarket options, such as more frequent failures, shorter lifespans, and possible voiding of other warranties.

| Factor | OEM Parts | Aftermarket Parts |

| Price | Higher initial cost | Lower initial cost |

| Quality & Fit | Guaranteed perfect fit and performance | Variable; can range from excellent to poor |

| Warranty | Usually comprehensive and backed by the manufacturer | Varies by supplier; often shorter or less comprehensive |

| Availability | May have longer lead times | Often widely available from multiple sources |

| Long-Term Value | Higher reliability can lead to lower total cost of ownership | Lower reliability may increase downtime and repair costs |

Strategies for Reducing Your Total Spare Parts Costs

Reducing costs in tower crane spare parts procurement is not solely about negotiating a lower unit price. It involves a holistic view of the Total Cost of Ownership (TCO), which includes the purchase price, storage, downtime, freight, and the frequency of replacement. Effective cost-reduction strategies are proactive and strategic. Implementing a predictive maintenance program is a cornerstone of this approach; by using data and regular inspections to predict failures before they happen, you can schedule repairs during planned downtime, avoid emergency premiums, and extend the life of components. Another key strategy is rationalizing your inventory, which means strategically stocking critical, high-failure-rate items while relying on trusted suppliers for slower-moving parts, thus reducing capital tied up in inventory and storage costs. Furthermore, building long-term relationships with key suppliers can open the door to volume discounts, preferential pricing, and value-added services like dedicated account management and faster shipping options.

- Implement Predictive Maintenance: Use data and regular inspections to anticipate failures and order parts in advance, avoiding emergency costs.

- Optimize Inventory Management: Use an ABC analysis to prioritize stocking critical (A-class) parts and reduce capital tied up in non-critical items.

- Negotiate Long-Term Contracts: Secure better pricing and terms by committing to a volume of business with a primary supplier.

- Consider Remanufactured Parts: For certain components, certified remanufactured parts can offer OEM-like performance at a significantly lower cost.

- Standardize Parts Across Fleet: If possible, standardize crane models to reduce the variety of spare parts needed, increasing your purchasing power.

Building a Resilient and Efficient Spare Parts Supply Chain

In today's globalized economy, a resilient supply chain for tower crane spare parts is not a luxury but a necessity. Resilience refers to the ability to anticipate, prepare for, and respond to disruptions—whether they are geopolitical, logistical, or natural—in order to maintain a continuous flow of essential components. Building such a supply chain requires deliberate planning and diversification. Relying on a single supplier, even a very good one, is a significant risk. Developing a shortlist of qualified alternative suppliers ensures you have options if your primary partner faces a stockout or logistical nightmare. Embracing technology is also crucial; modern inventory management systems provide real-time visibility into stock levels, automate reordering processes, and generate valuable data analytics to forecast future demand more accurately, preventing both overstocking and stockouts.

- Diversify Your Supplier Base: Identify and qualify secondary suppliers in different geographic regions to mitigate risk.

- Leverage Technology: Implement inventory management software for real-time tracking and demand forecasting.

- Establish Clear Communication Protocols: Ensure seamless information flow between your maintenance, operations, and procurement teams.

- Develop a Risk Management Plan: Map your supply chain and identify single points of failure; develop contingency plans for critical part shortages.

- Build Strategic Partnerships: Work with suppliers who view the relationship as a partnership and are willing to collaborate on solving supply chain challenges.

FAQ

What is the lead time for tower crane spare parts?

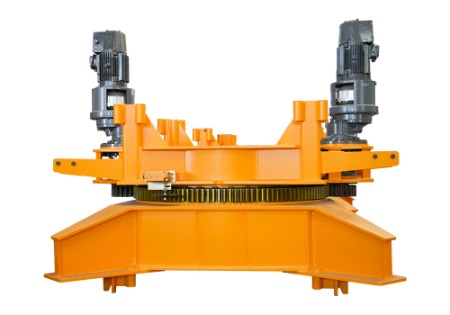

Lead times can vary significantly based on the part's complexity, source (OEM or aftermarket), and your geographic location. Common wear parts like wire ropes or brake pads are often readily available and can be shipped within days. For major, crane-specific components like a slewing ring or motor, lead times from an OEM can range from several weeks to several months, especially if the part is made-to-order. This is why maintaining a strategic inventory of critical parts and fostering strong supplier relationships for emergency tower crane parts delivery is crucial to minimize project downtime.

How can I verify the quality of an aftermarket spare part?

Verifying the quality of an aftermarket part requires due diligence. First, request detailed specifications and material certifications from the supplier and compare them to the OEM's specifications. Second, inquire about the supplier's testing procedures and quality control measures. Third, seek out reviews and testimonials from other customers, specifically those in similar industries. Finally, if possible, order a sample part for a non-critical application to test its performance and durability before making a larger purchase. This process helps in finding reliable aftermarket tower crane parts that won't compromise safety.

What are the most critical spare parts to keep in stock?

The most critical parts to stock are those that are essential for safe operation, have a high failure rate, and would cause significant downtime if they failed. This typically includes electrical components like frequency drives and PLCs, mechanical wear items like brake systems, wire ropes, and hooks, and hydraulic components such as pumps and valves. Conducting a failure mode and effects analysis (FMEA) on your specific crane models will provide a data-driven answer tailored to your equipment and usage patterns, forming the basis of an effective tower crane spare parts inventory management strategy.

Is it worth repairing a part versus replacing it?

The decision to repair or replace depends on a cost-benefit analysis. Factors to consider include the cost of the new part versus the repair cost, the expected remaining lifespan of the repaired part, and the criticality of the component. For complex and expensive parts like a gearbox or motor, professional repair or remanufacturing can often restore performance to like-new condition at 50-70% of the cost of a new part, making it a very valuable cost-saving tip for crane maintenance. However, for safety-critical components or parts where a repair would not guarantee reliability, replacement is almost always the recommended course of action.

How do I manage the warranty for replaced parts?

Warranty management is a key administrative task. Always keep detailed records of the purchase date, invoice, installation date, and the serial number of the installed part. Register the part with the manufacturer or supplier if required. Understand the full terms of the warranty, including its duration, what it covers (e.g., parts, labor), and the procedure for making a claim. Using a computerized maintenance management system (CMMS) can automate warranty tracking and send alerts before warranties expire, ensuring you get the full value from your purchases and simplifying the process for procurement of tower crane spare parts.

English

English русский

русский Español

Español 中文简体

中文简体